U/W INSPECTION(CCTV, VIDEO, PHOTO)

C.C TV Inspection

- Use of top spec digital cctv monitoring system

to record and edit on site. Videos can be

transmitted to smart phones, hardware, and

even to automotive display panel. Multiple

systems can be positioned allowing simultaneous

monitoring on site.

Photo Inspection

- Shooting crisp and high quality photos using HD digital camera.

Video Inspection

- Shooting crisp and high quality videos using HD digital recorder.

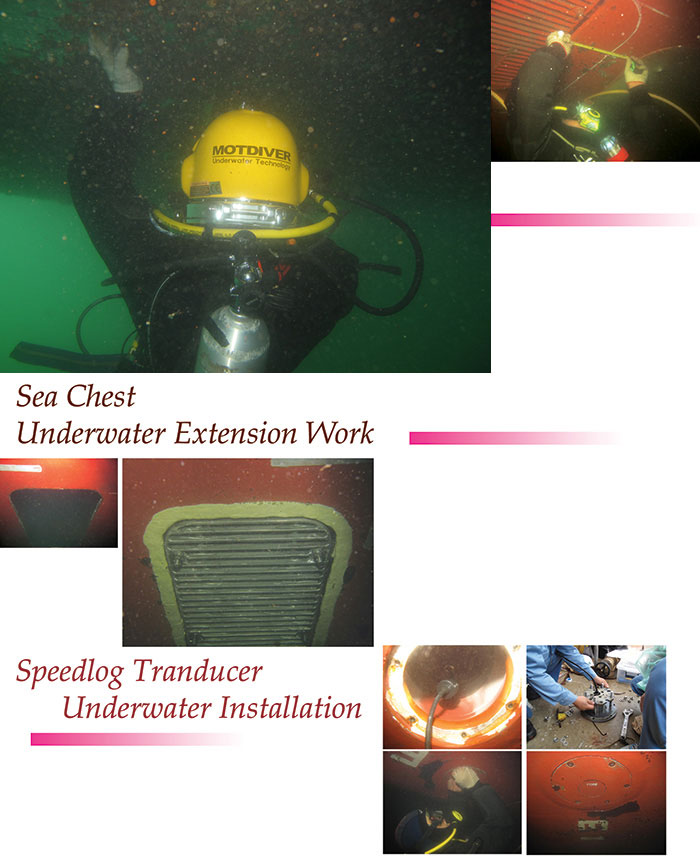

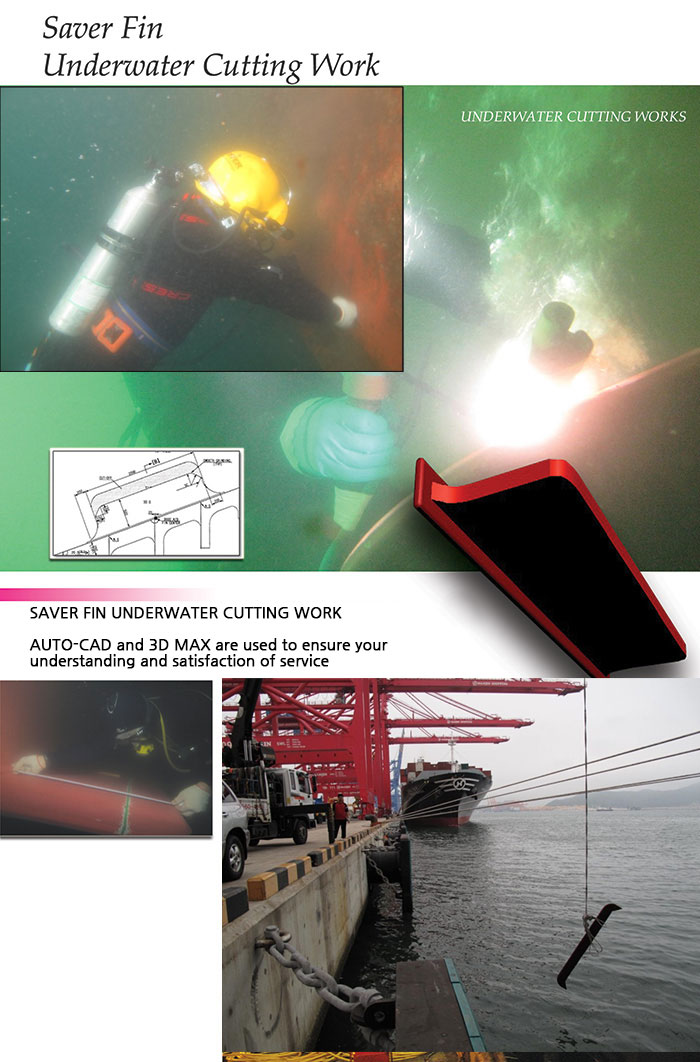

U/W INSTALLATION, CUTTING

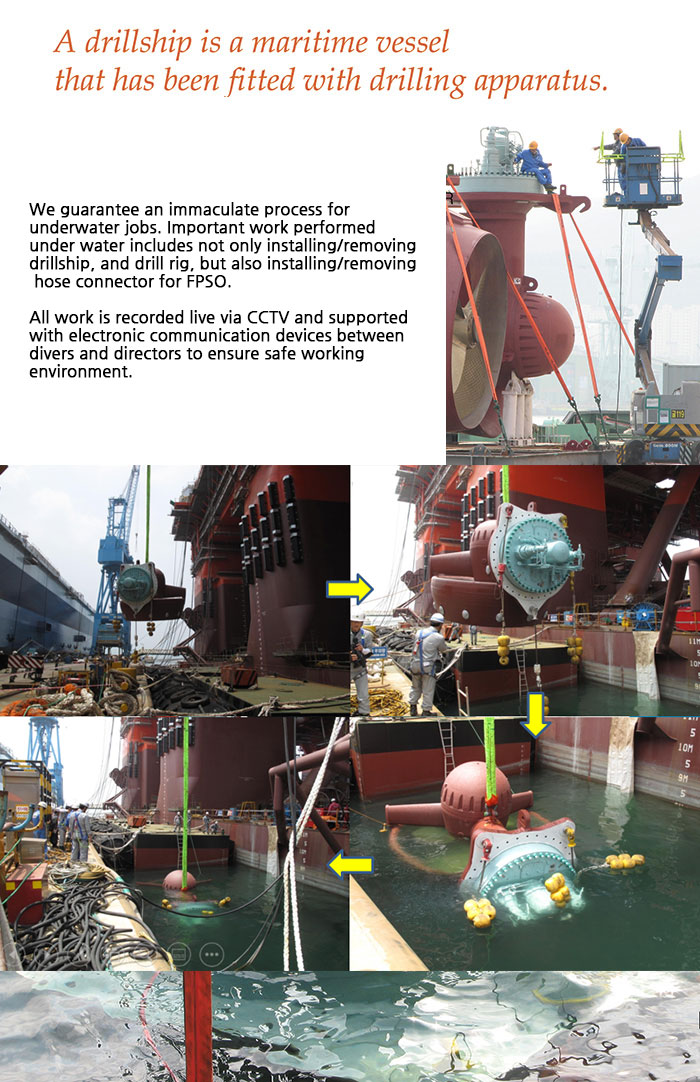

- U/W THRUSTER INSTALLATION

Azimuth Thruster (Azimuth Thruster Underwater Installation)

- Azimuth Thruster Underwater Installation of the Drillship & Drill rig

- U/W COFFERDAM WORKS

(Underwater Rudder Repair Work By Cofferdam box)

A cofferdam

A cofferdam is an enclosure created beneath the water for the purpose of creating a dry working environment.

Cofferdam is used widely in the field of commercial

diving technology in order to repair vessels in water. With the construction of cofferdam, vessels with cracks or dents on the side or bottom panel can be easily repaired. It is also used for major reconstruction

job for bow thrusters, propellers and rudders.

Constructing cofferdam is a complex work

requiring diverse skill sets and expertise.

Due to its complexity, MOT continuously

attends relevant seminars and training

to uphold with industry standards.

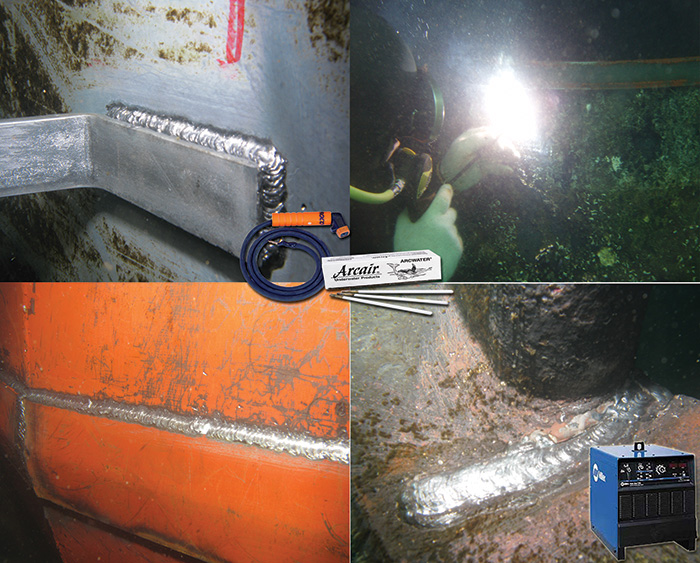

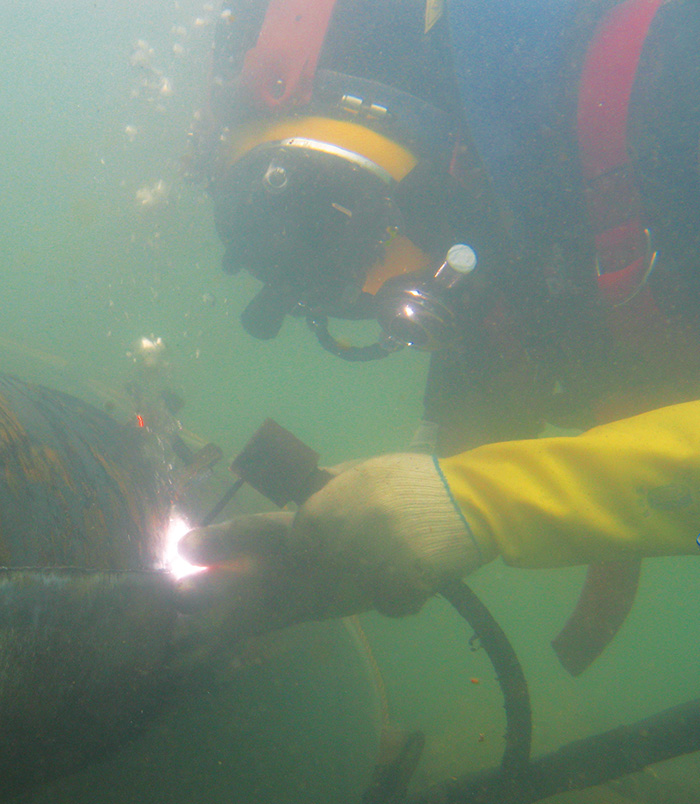

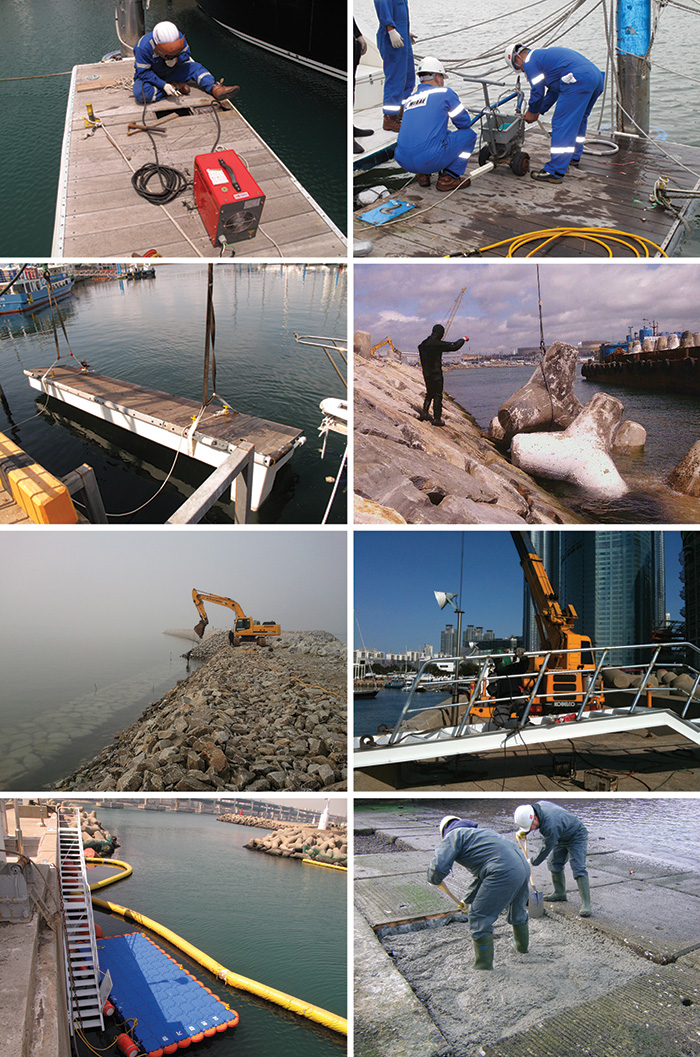

- U/W WELDING

Speciality Welds Underwater Wet Welding

- Although methods of underwater welding were

developed in 1801 by Humphrey Davey, it wasn’t until 1917 when underwater welding

was used to prevent water leakage on vessels.

Subsequently, this method was applied by the Americans during World War II for their vessels.

Since then there has been many ongoing research and developments to improve underwater welding. Continuous development of welding equipment and welding sticks has significantly contributed to modern day work.

MOT makes an effort to meet higher standard of work by employing Original Welding Stick and Generator.

Underwater Pipe Line Welding Repair.

- Underwater welding work includes restoring vessels with corrosion, cracking and discoloration, installation and removal of parts, refurbishing underwater pipelines, repairing docks

and harbors, and replacing old ANODE or rope guards.

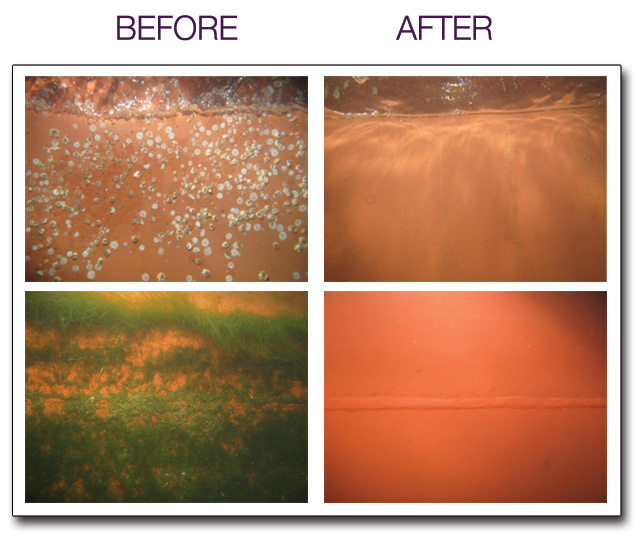

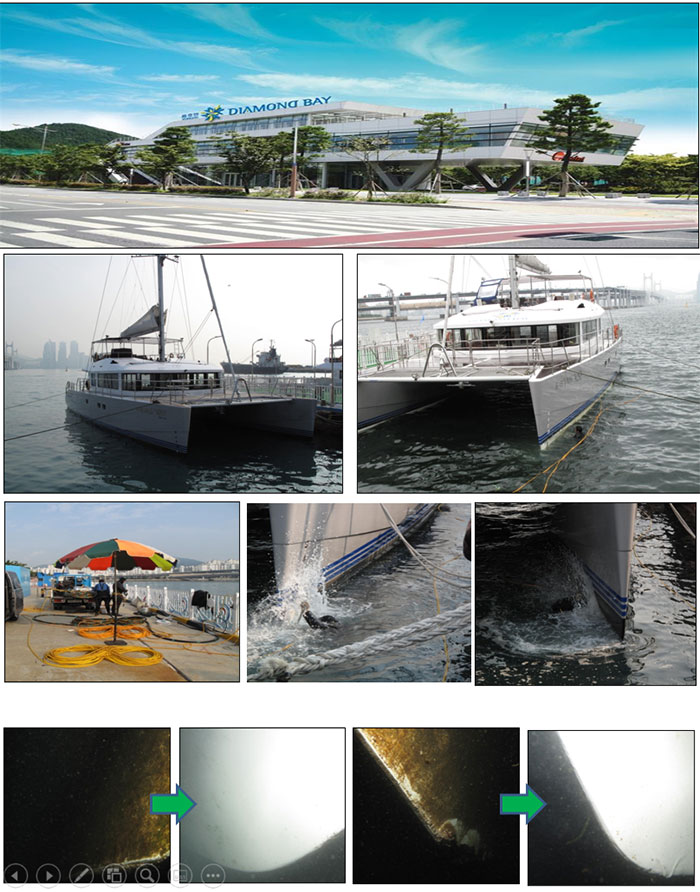

Underwater Hull Cleaning Work

Underwater Polishing Work

- U/W HULL CLEANING

(Underwater Hull Cleaning by High Pressure Water jet)

A high pressure waterjet is generally remove the Seaweed & barnacles.

It is available Silicon .

A high pressure waterjet is used to remove seaweed, seagrass and barnacles without the danger of removing vessel paint. Cleaning can benefit vessels by increasing fuel efficiency, reducing sailing time,

protecting and increasing life expectancy of vessel

panels from corrosion. Additionally, other important parts such as, bottom sensor, I.C.C.P, sea chest can

be cleaned for enhanced performance.

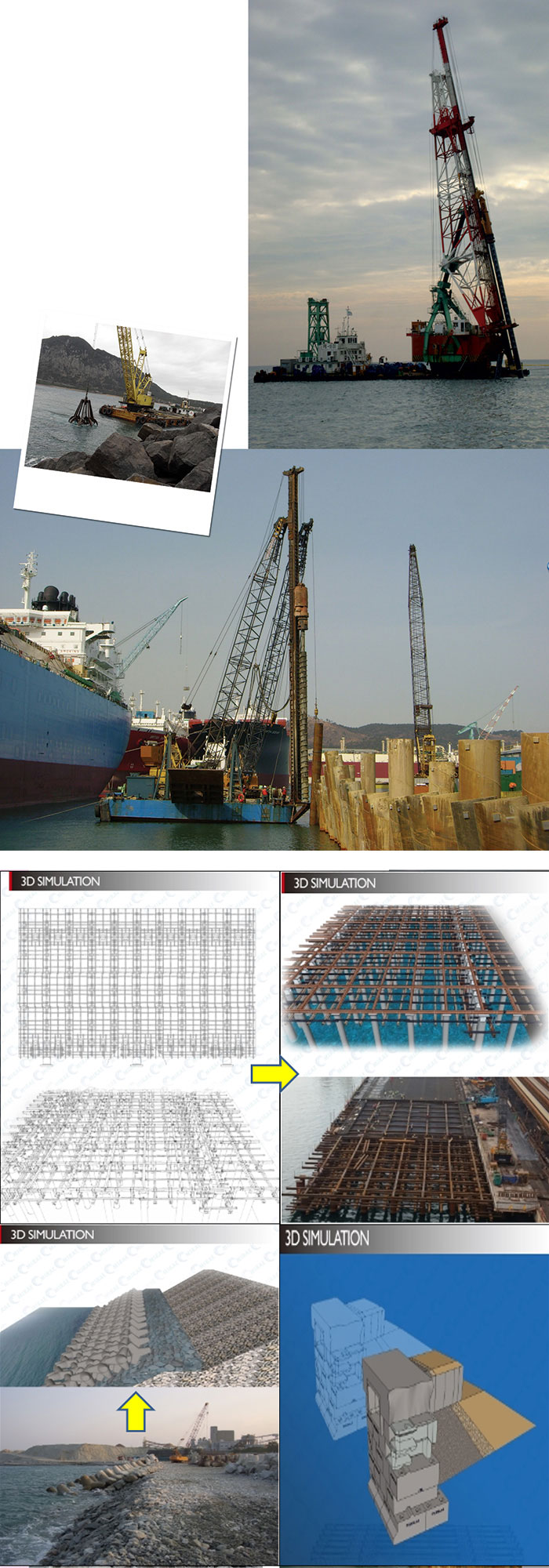

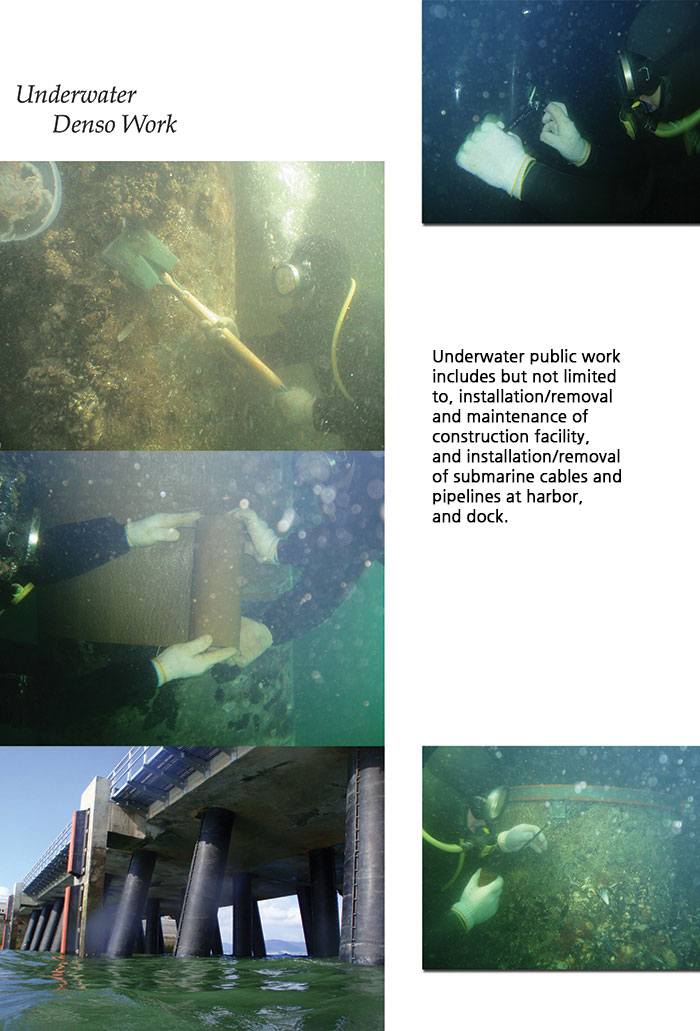

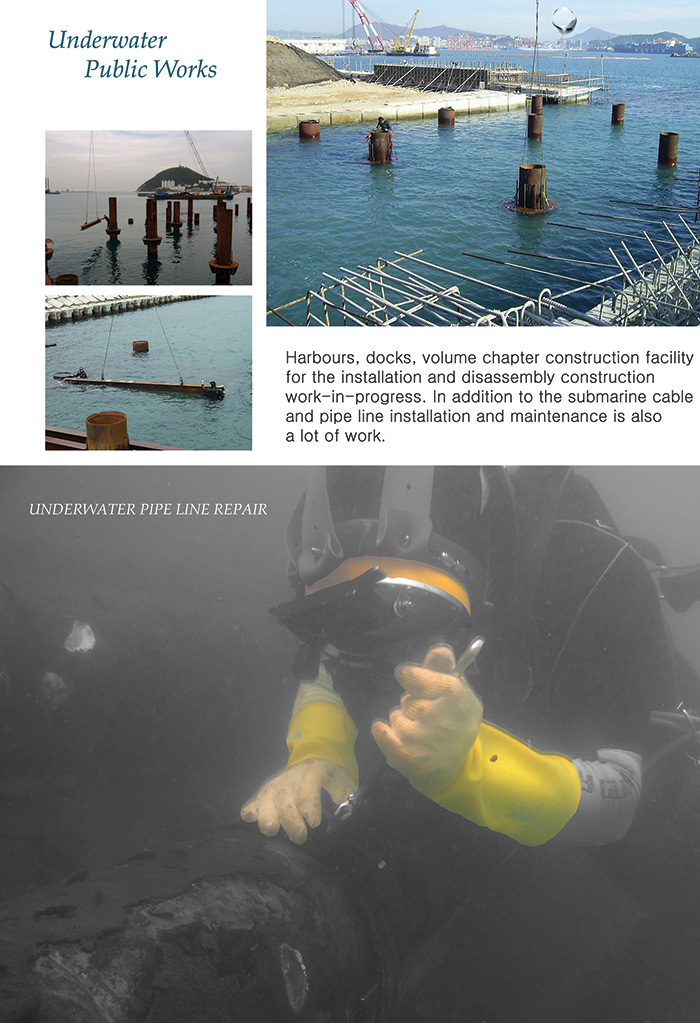

- U/W Construction Engeneering

Marine Structure Underwater Repair Works.

- MEGA Yacht U/W management

we support yacht management system for the safety sailing

And saved of yacht management cost

.

|